Hardened surfaces on contact adhesive spray guns typically refer to specific components or areas that have undergone a surface hardening treatment. This treatment involves modifying the surface layer of a material to enhance its hardness, wear resistance, and durability. The goal is to provide better resistance to abrasion and extend the lifespan of critical components. Here are some key points regarding hardened surfaces in contact adhesive spray guns:

Components Subjected to Wear: Hardened surfaces are often applied to components that experience wear during the operation of the spray gun. Common areas include needle tips, nozzles, or any other parts that come into contact with abrasive materials or undergo repeated movement.

Surface Hardening Techniques: Various techniques can be used to harden surfaces. Heat treatment processes, such as carburizing or nitriding, can introduce carbon or nitrogen into the surface layer, creating a hardened outer layer while maintaining a more ductile core.

Coating Technologies: Surface coatings, such as ceramic coatings or certain metal coatings, can provide hardness and wear resistance. PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) processes are examples of coating technologies used to enhance surface properties.

Benefits of Hardened Surfaces:

Wear Resistance: Hardened surfaces resist wear and abrasion, ensuring that critical components maintain their integrity over an extended period.

Extended Lifespan: The increased wear resistance contributes to a longer lifespan for components, reducing the frequency of replacements and maintenance.

Improved Performance: Hardened surfaces contribute to consistent performance by maintaining the geometry and functionality of components over time.

Needle Tips and Nozzles: In contact adhesive spray guns, the needle tip and nozzle are particularly critical components that may benefit from hardened surfaces. These components are involved in the precise control and atomization of the adhesive spray.

Materials Used: Depending on the specific application and requirements, hardened surfaces may be achieved through treatments of materials like stainless steel, tool steel, or other alloys that respond well to surface hardening processes.

Considerations for Adhesive Characteristics: The choice of hardening methods and materials should consider the characteristics of the adhesives being used. Compatibility with adhesives is crucial to prevent issues such as coating delamination or chemical reactions.

Maintenance: While hardened surfaces enhance durability, routine maintenance and proper cleaning remain important. Regular maintenance practices help prevent the buildup of adhesive residues and ensure optimal performance.

Manufacturer's Specifications: It's important to follow the manufacturer's specifications and recommendations regarding the use, maintenance, and replacement of components with hardened surfaces to maximize the effectiveness of the treatment.

In summary, the implementation of hardened surfaces in contact adhesive spray guns is a deliberate choice to enhance wear resistance and extend the overall lifespan of critical components. It's part of the design strategy to ensure consistent and reliable performance in applications where durability is essential.

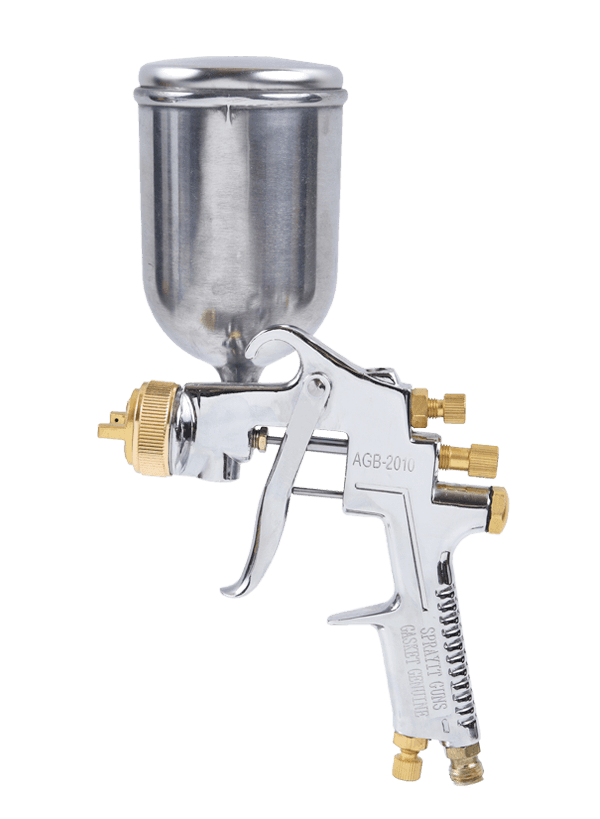

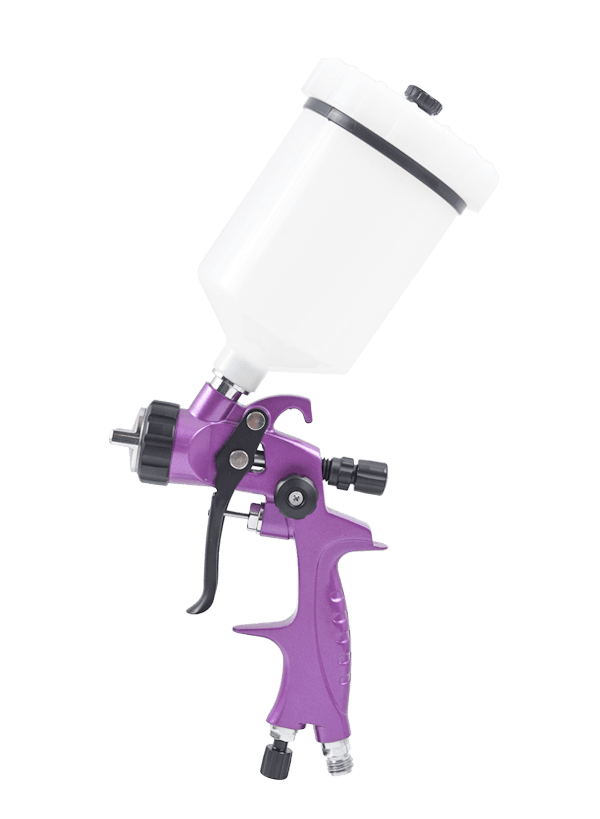

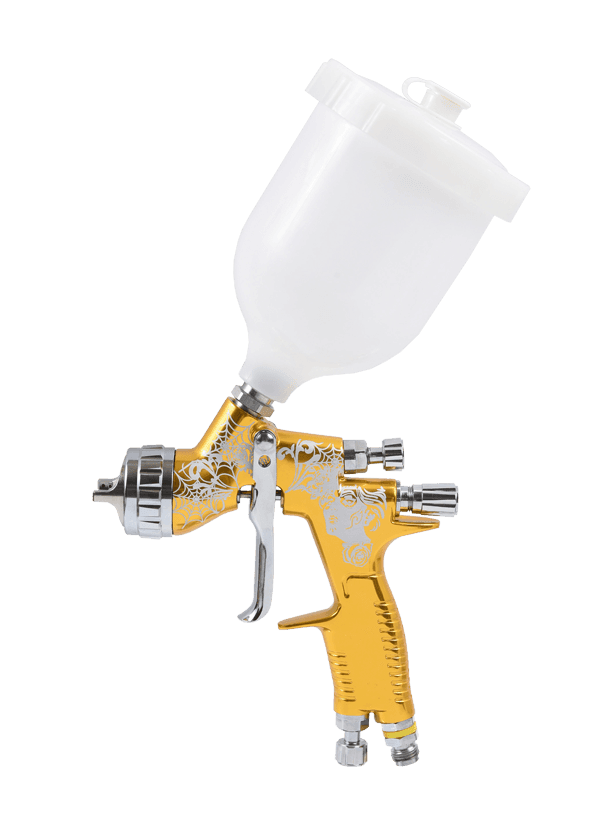

PRODUCTS SERIES

-

Water-based paint spray gun -HVLP-H-827

-

Water-based paint spray gun -HVLP-1500C

-

Water-based paint spray gun -HVLP-2020

-

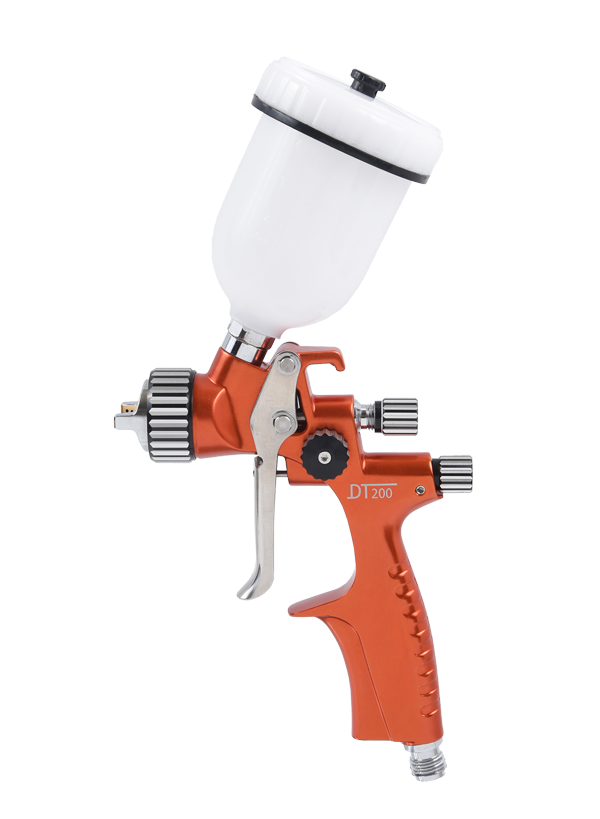

Water-based paint spray gun -HVLP-DT200

-

Water-based paint spray gun -HVLP-E-520

-

Water-based paint spray gun -HVLP-H-827 set-blue

-

Water-based paint spray gun -HVLP-H-827-Suit-silver

-

Water-based paint spray gun -HVLP-W-10

-

Water-based paint spray gun -HVLP-W-20

-

Water-based paint spray gun -HVLP-W-40

English

English Español

Español