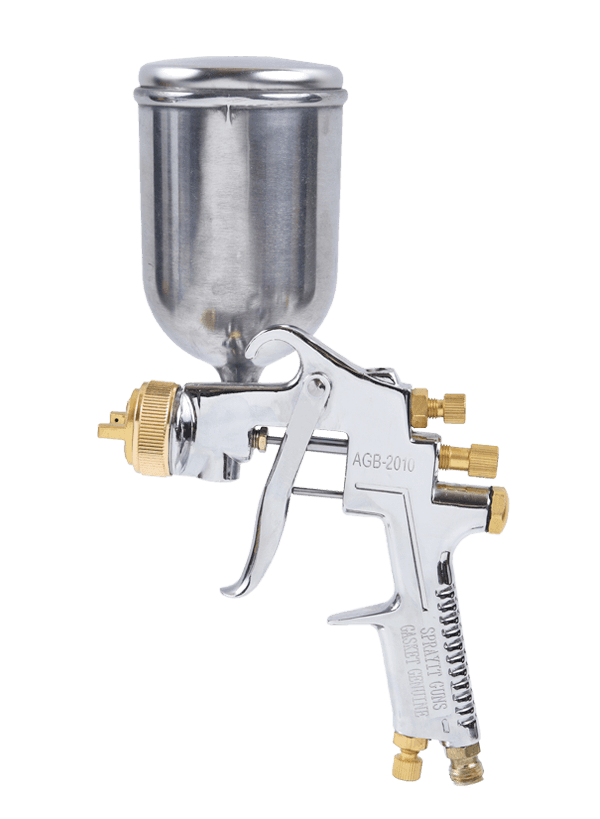

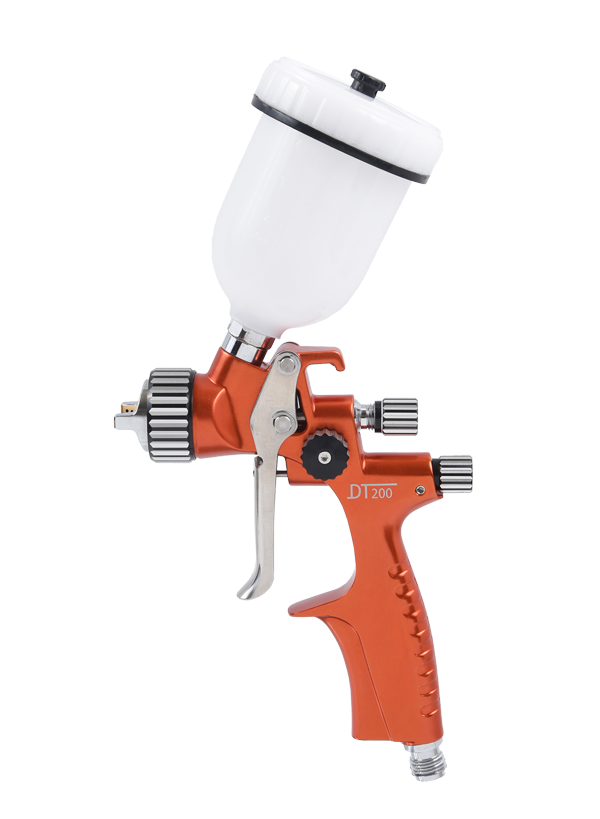

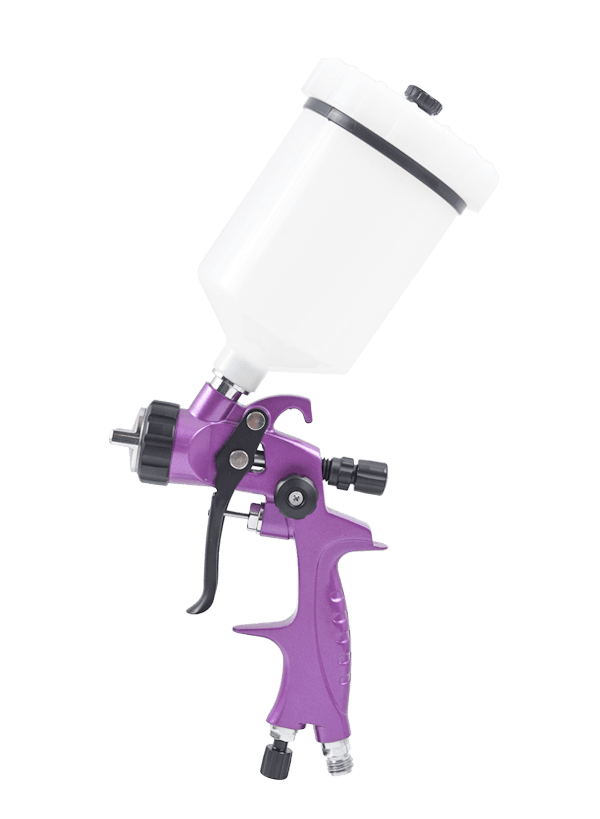

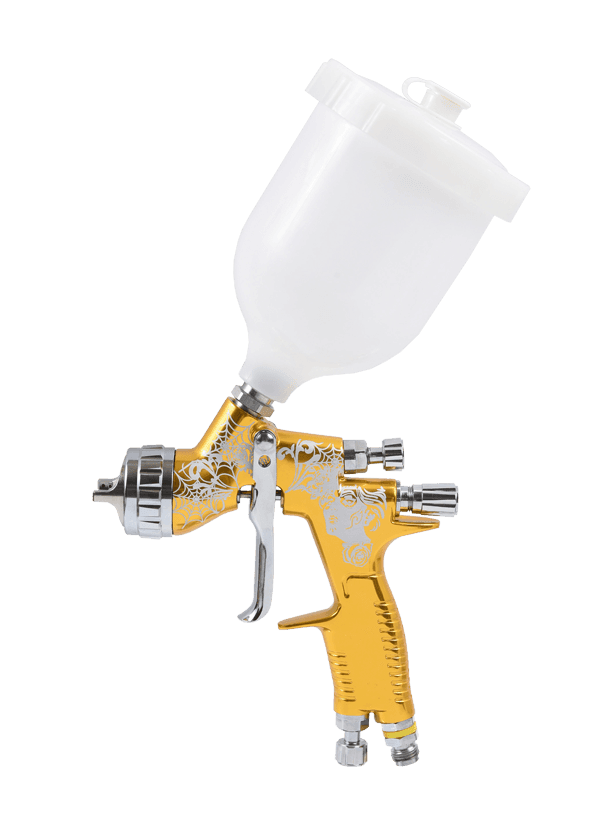

Optimizing the efficiency and effectiveness of a high-pressure spray gun for different coating materials and application requirements involves several key considerations and techniques:

Selecting the Right Nozzle: Choose a nozzle size and configuration appropriate for the viscosity and particle size of the coating material. Smaller nozzles are typically used for finer coatings, while larger nozzles are suitable for thicker materials.

Adjusting Pressure Settings: Fine-tune the pressure settings of the

spray gun to match the viscosity and flow characteristics of the coating material. Higher pressures may be needed for thicker materials, while lower pressures are suitable for finer coatings to prevent overspray and achieve uniform coverage.

Optimizing Spray Patterns: Adjust the spray pattern of the gun to match the shape and size of the surface being coated. This ensures even coverage and minimizes material wastage. For example, a narrow fan pattern may be used for precise applications, while a wider pattern is suitable for large surface areas.

Maintaining Proper Gun-to-Surface Distance: Maintain a consistent distance between the spray gun and the surface being coated to achieve the desired film thickness and finish. Too close of a distance can result in excessive buildup, while too far can lead to uneven coverage.

Controlling Air Flow: For air-assisted spray guns, adjust the air flow to atomize the coating material effectively and achieve the desired spray pattern. Proper air flow control helps in controlling overspray and improving transfer efficiency.

Preventing Overspray: Use masking or shielding techniques to prevent overspray onto adjacent surfaces or areas not intended for coating. This helps reduce material wastage and improves the quality of the finish.

Thinning Coating Materials: Adjust the viscosity of the coating material by adding appropriate thinners or solvents. Thinning may be necessary to achieve the desired flow and atomization characteristics for optimal spraying.

Maintaining Clean Equipment: Regularly clean and maintain the spray gun, including the nozzle, fluid passages, and filters, to prevent clogging and ensure consistent performance. Proper maintenance also extends the lifespan of the equipment.

Testing and Adjusting: Conduct test sprays and make adjustments as needed to optimize the spray gun settings for the specific coating material and application requirements. Fine-tuning may be necessary to achieve the desired finish and coverage.

By considering these factors and implementing appropriate techniques, the efficiency and effectiveness of a high-pressure spray gun can be optimized for various coating materials and application scenarios, resulting in superior finish quality and reduced material wastage.

English

English Español

Español