Cleaning and maintaining a contact adhesive spray gun is essential to ensure its optimal performance and longevity. Here are the general steps to clean and maintain a contact adhesive spray gun:

Cleaning:

Safety Precautions:

Before you start cleaning the spray gun, make sure it is disconnected from the air supply and any power sources. Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

Empty the Reservoir:

If there is any adhesive remaining in the gun's reservoir, carefully empty it into a suitable container. Be cautious not to spill adhesive on yourself or the surrounding area.

Disassemble the Gun:

Follow the Contact Adhesive Spray Guns Manufacturers's instructions to disassemble the spray gun. This typically involves removing the fluid nozzle, needle, air cap, and any other removable parts. Refer to the user manual for guidance on disassembly.

Clean Removable Parts:

Submerge the removable parts (fluid nozzle, needle, air cap, etc.) in an appropriate solvent or adhesive cleaner recommended by the manufacturer.

Use a brush or cleaning tool to remove any adhesive residue from these parts. Be thorough to ensure all adhesive deposits are removed.

Clean the Reservoir:

Wipe out the interior of the gun's reservoir with a clean cloth or paper towels to remove any remaining adhesive. Use an appropriate solvent if needed.

Flush the Gun:

Connect the spray gun to a source of clean solvent or adhesive cleaner.

With the air supply disconnected, trigger the gun to spray the cleaning solvent through the gun until it runs clear. This helps flush out any adhesive residue from the internal passages.

Clean the Exterior:

Wipe down the exterior of the spray gun with a cloth or paper towels to remove any adhesive splatter or residue.

Maintenance:

Inspect Seals and Gaskets:

Check the seals and gaskets for signs of wear or damage. Replace any damaged or worn seals to prevent leaks.

Lubrication:

Lubricate any moving parts or threads with a lubricant recommended by the Contact Adhesive Spray Guns Manufacturers to prevent sticking and ensure smooth operation.

Reassemble the Gun:

Reassemble the spray gun following the Contact Adhesive Spray Guns Manufacturers 's instructions, ensuring that all parts are properly seated and tightened.

Pressure Adjustment:

Reconnect the spray gun to the air supply and test it with a clean solvent to ensure that it is spraying properly.

Adjust the air pressure to the level required for your application.

Testing:

Perform a test spray with the adhesive to ensure that the gun is functioning correctly and that the adhesive is being applied evenly.

Storage:

If you won't be using the spray gun for an extended period, consider removing any adhesive from the gun and storing it in a clean, dry place.

Regular Maintenance:

Periodically clean and maintain the spray gun as needed, especially after heavy use or when switching between different adhesive types.

Always follow the Contact Adhesive Spray Guns Manufacturers's guidelines and recommendations for cleaning and maintaining your specific contact adhesive spray gun, as different models may have unique requirements. Proper cleaning and maintenance will help ensure consistent performance and prolong the life of your spray gun.

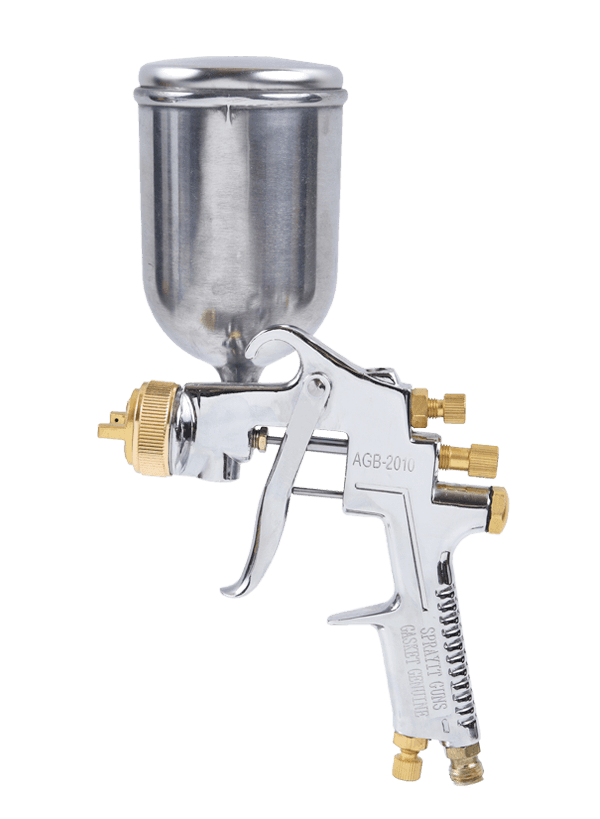

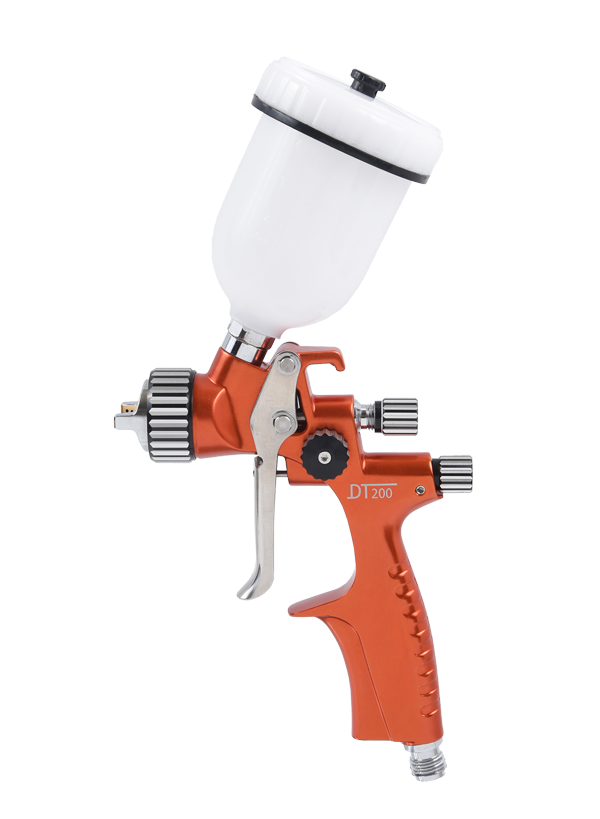

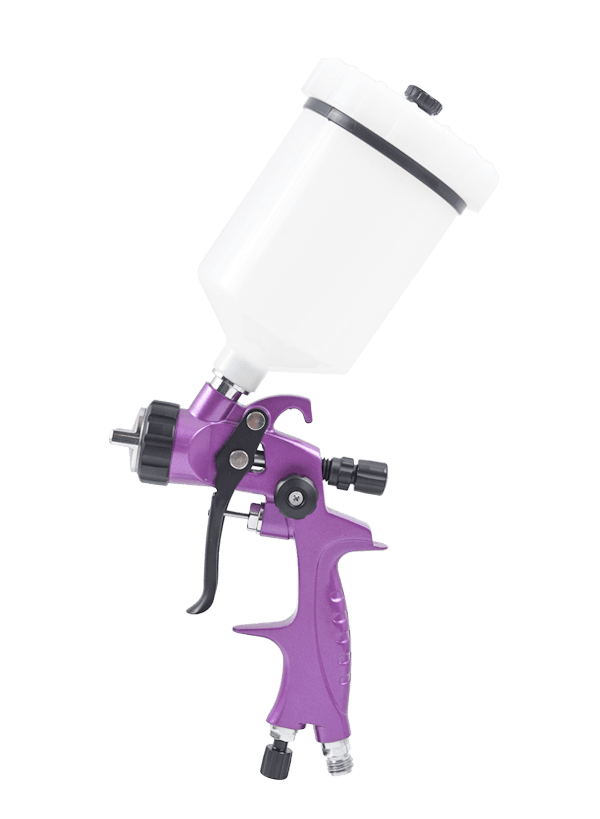

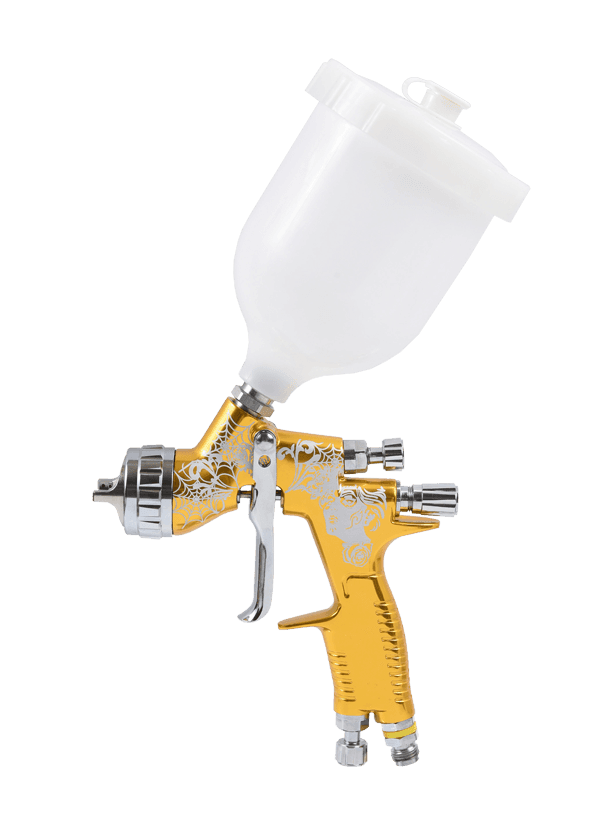

PRODUCTS SERIES

-

Water-based paint spray gun -HVLP-H-827

-

Water-based paint spray gun -HVLP-1500C

-

Water-based paint spray gun -HVLP-2020

-

Water-based paint spray gun -HVLP-DT200

-

Water-based paint spray gun -HVLP-E-520

-

Water-based paint spray gun -HVLP-H-827 set-blue

-

Water-based paint spray gun -HVLP-H-827-Suit-silver

-

Water-based paint spray gun -HVLP-W-10

-

Water-based paint spray gun -HVLP-W-20

-

Water-based paint spray gun -HVLP-W-40

English

English Español

Español