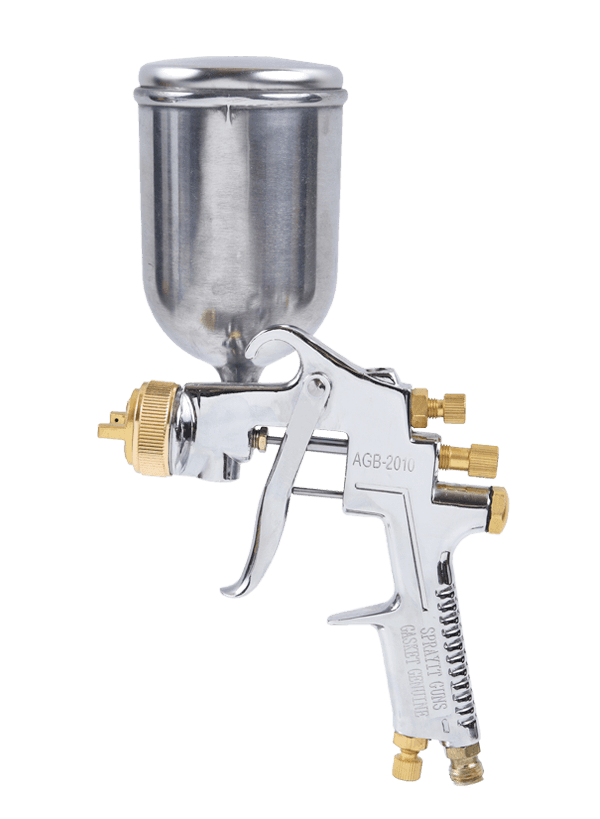

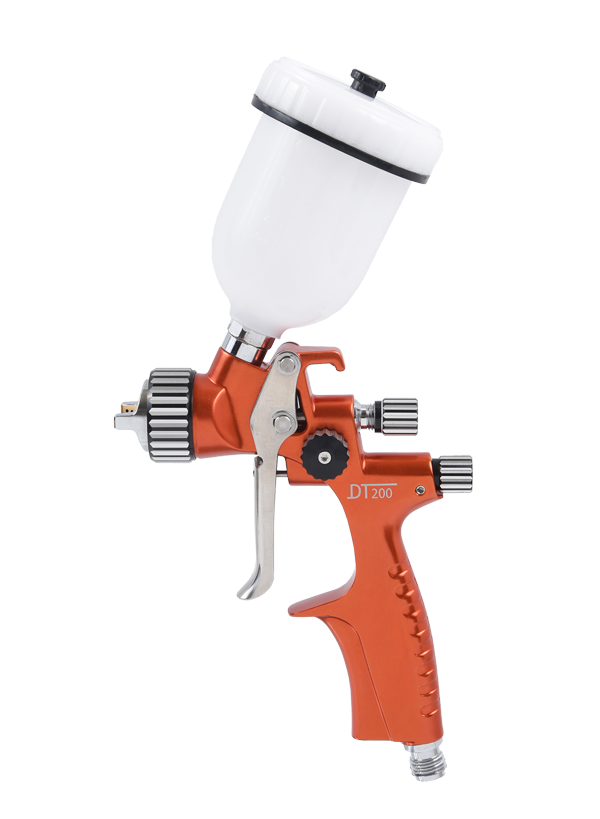

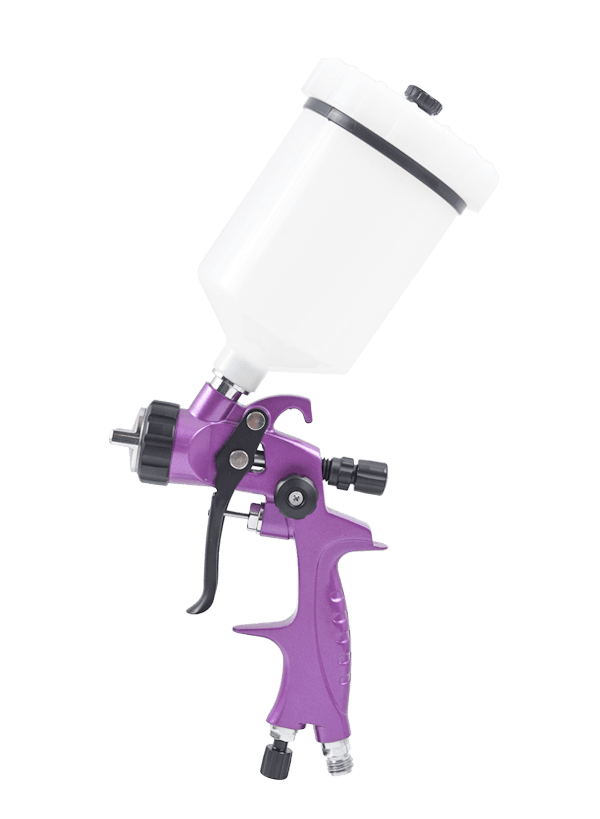

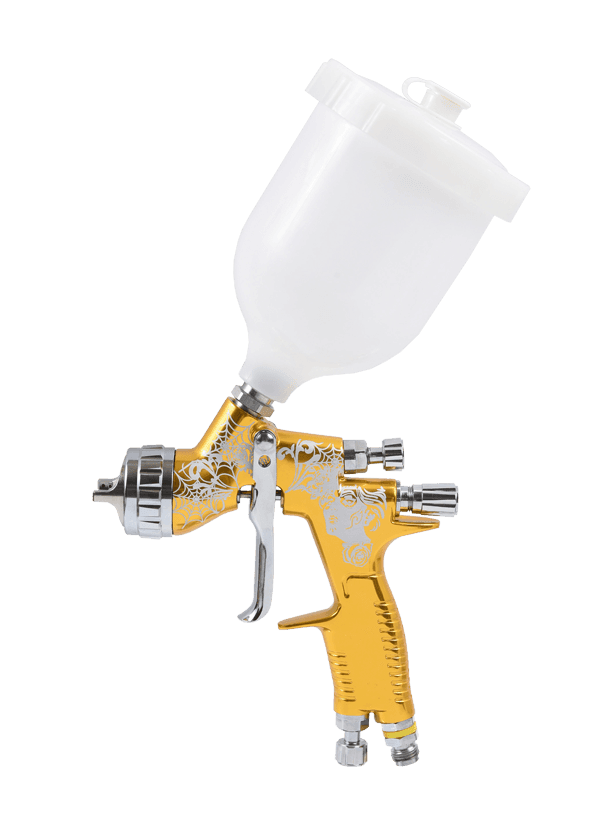

The choice of a spray gun plays a crucial role in determining the efficiency of a painting or coating process. Several factors related to the spray gun can influence the overall efficiency of the application. Here are key considerations:

Transfer Efficiency:

The design and technology of the spray gun can impact transfer efficiency, which measures the percentage of coating material that actually adheres to the substrate. High transfer efficiency indicates less overspray and material waste.

Spray Pattern Control:

Different spray guns offer varying degrees of control over the spray pattern. The ability to adjust the pattern shape and size allows for precise application on different surfaces, contributing to efficient coverage.

Atomization Quality:

Atomization refers to the process of breaking the coating material into fine droplets. A spray gun with good atomization produces a fine mist, resulting in a more even and consistent coating. This is crucial for achieving a smooth finish and minimizing the need for additional coats.

Pressure Control:

The ability to control and adjust the

spray gun pressure is essential. It allows for customization based on the viscosity of the coating material and the requirements of the application. Proper pressure control contributes to uniform coverage and efficient material use.

Material Compatibility:

The spray gun must be compatible with the specific type and viscosity of the coating material being used. A well-matched spray gun ensures optimal performance, preventing issues like clogging or uneven application.

Nozzle and Tip Selection:

The choice of nozzle and tip size is critical. The correct combination contributes to the desired spray pattern, coverage, and material flow. Proper selection minimizes overspray and ensures efficient use of the coating material.

Ease of Cleaning and Maintenance:

An efficient spray gun design includes features that make cleaning and maintenance straightforward. Easy disassembly and accessibility to critical components simplify the cleaning process, reducing downtime and ensuring consistent performance.

User Comfort and Ergonomics:

The design of the spray gun handle, weight distribution, and trigger control impact user comfort. An ergonomic design reduces operator fatigue during prolonged use, contributing to overall efficiency and productivity.

Durability and Reliability:

A reliable spray gun that withstands the demands of the application environment contributes to efficiency by reducing the likelihood of equipment failures or downtime. Durability is especially crucial in high-production settings.

Adaptability to Application Requirements:

Different applications may have specific requirements, such as varying spray angles, distances, or coating thicknesses. The spray gun should be adaptable to these requirements, allowing for efficient customization based on the task at hand.

Technology and Automation:

Advanced spray gun technologies, including automated features and digital controls, can enhance efficiency by providing precision and consistency in coating application. Automated systems may also reduce manual labor and increase throughput.

the choice of a spray gun significantly impacts the efficiency of a painting or coating process. By considering factors such as transfer efficiency, spray pattern control, atomization quality, pressure control, and user comfort, operators can select a spray gun that contributes to a more efficient, cost-effective, and high-quality coating application.

English

English Español

Español