Minimizing overspray is essential for efficient and controlled application when using contact adhesive spray guns. Overspray can result in wasted material, uneven coatings, and potential environmental and safety issues. Here are ways overspray is minimized, and features that help control and contain overspray:

Air Pressure and Atomization:

Adjusting the air pressure and atomization settings on the contact adhesive spray gun allows for better control over the spray pattern, reducing the likelihood of overspray.

Proper Nozzle Selection:

Choosing the appropriate nozzle size and type for the specific application helps optimize the spray pattern, minimizing overspray. Nozzles with fine atomization are often selected for precise control.

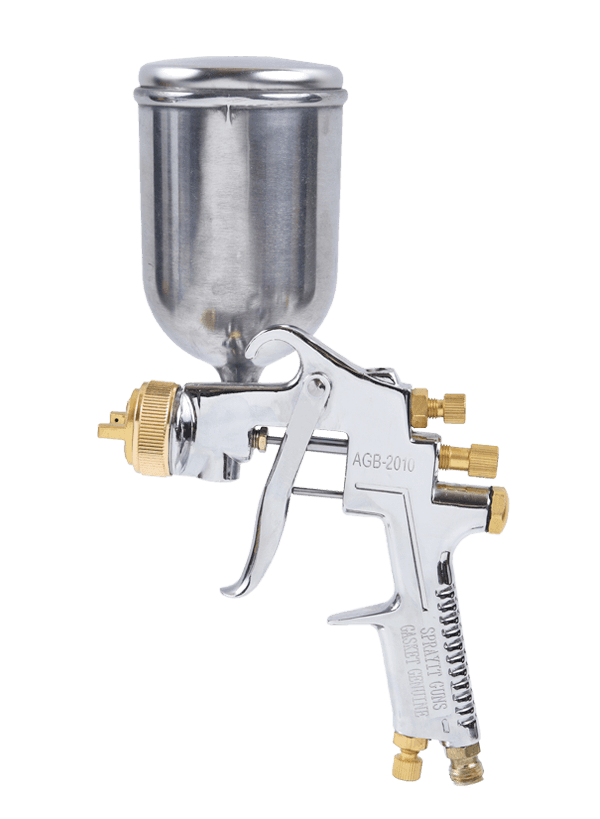

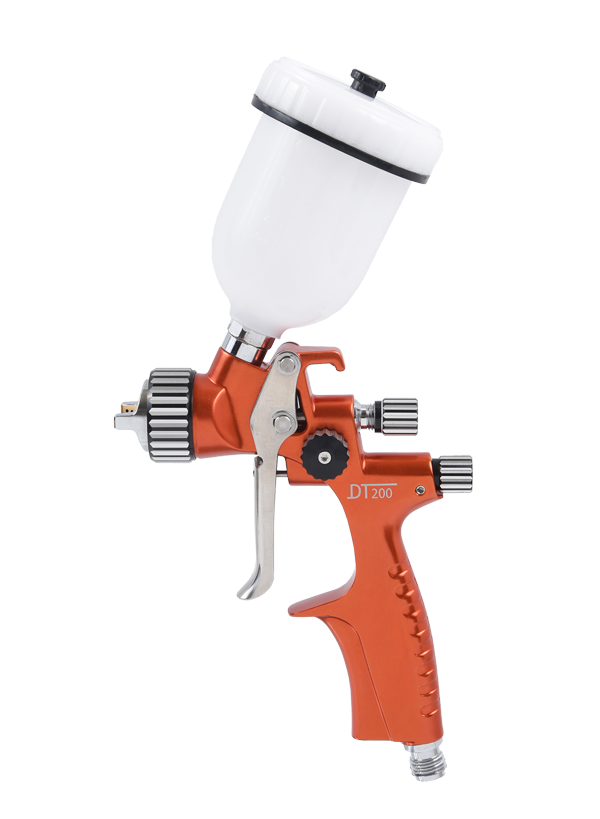

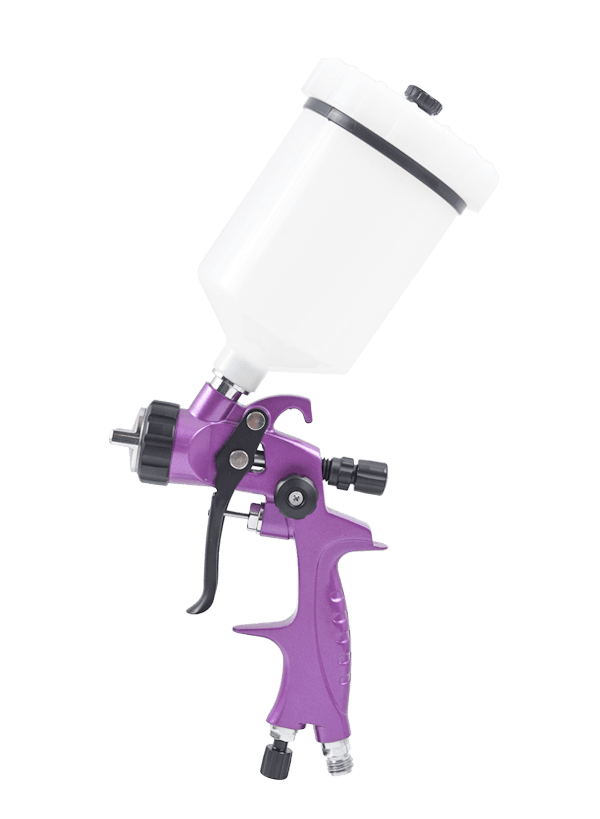

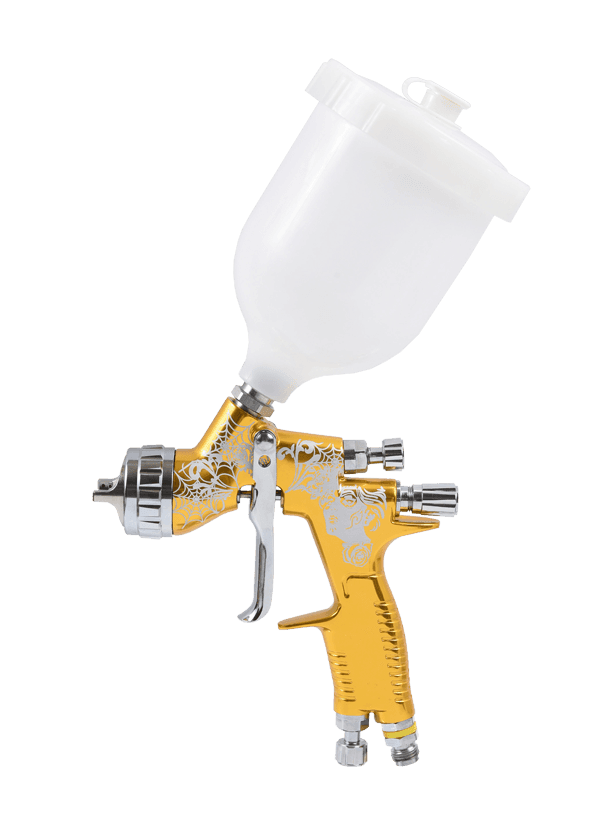

Spray Gun Design:

Modern contact adhesive spray guns are designed with features that enhance control and minimize overspray. This includes improved nozzle designs and air cap configurations to achieve more focused and controlled spraying.

Adjustable Spray Patterns:

Contact adhesive spray guns often feature adjustable spray patterns, allowing users to modify the width and shape of the spray according to the size and contours of the substrate. This flexibility helps minimize overspray.

HVLP (High Volume, Low Pressure) Technology:

HVLP technology is designed to deliver a high volume of air at low pressure, resulting in reduced overspray. HVLP

contact adhesive spray guns are known for their efficiency and compliance with environmental regulations.

Transfer Efficiency:

High transfer efficiency in contact adhesive spray guns means more of the adhesive is directed to the target surface and less is wasted as overspray. Efficient transfer systems contribute to material savings.

Use of Spray Booths or Enclosures:

Conducting spraying operations within enclosed spray booths or controlled environments helps contain overspray. Booths often have extraction systems to capture and filter airborne particles.

Overspray Shields or Guards:

Some contact adhesive spray guns come equipped with overspray shields or guards that help direct the spray pattern precisely onto the substrate, reducing the chances of overspray escaping.

Masking and Taping:

Masking and taping off areas that do not require adhesive application is a manual method to control overspray. This is particularly useful for intricate or detailed surfaces.

Distance and Angle Control:

Controlling the distance between the spray gun and the substrate, as well as adjusting the spraying angle, helps manage overspray. Maintaining a consistent distance and angle is crucial for uniform application.

Anti-Drip Features:

Some contact adhesive spray guns include anti-drip features to prevent excess adhesive from dripping when the trigger is released. This helps reduce the risk of unintentional overspray.

Reduced Pressure During Trigger Release:

Implementing a system that reduces pressure or stops material flow when the trigger is released helps minimize overspray during non-application periods.

Environmental Considerations:

Operating contact adhesive spray guns in a controlled environment with minimal air movement reduces the chances of overspray drifting and contaminating nearby surfaces.

Use of Low-VOC (Volatile Organic Compounds) Adhesives:

Choosing low-VOC adhesives reduces the environmental impact and potential health concerns associated with overspray. These adhesives often have less solvent content.

Regular Maintenance:

Keeping the spray gun well-maintained, including cleaning and replacing worn parts, ensures that it continues to operate efficiently and minimizes the risk of overspray due to equipment issues.

Manufacturers provide guidelines and recommendations for optimizing contact adhesive spray gun performance, and operators should be trained to follow these guidelines for precise and controlled application. Additionally, compliance with environmental regulations and safety standards contributes to responsible overspray management.

English

English Español

Español