Choosing the correct contact adhesive applicator for your application requires considering several factors. Here are some steps to help you make an informed decision:

1.Identify Your Application Needs: Understand the specific requirements of your adhesive application. Consider factors such as the type and size of the surface to be bonded, the adhesive material, the desired coverage area, and the project scale (small-scale or industrial).

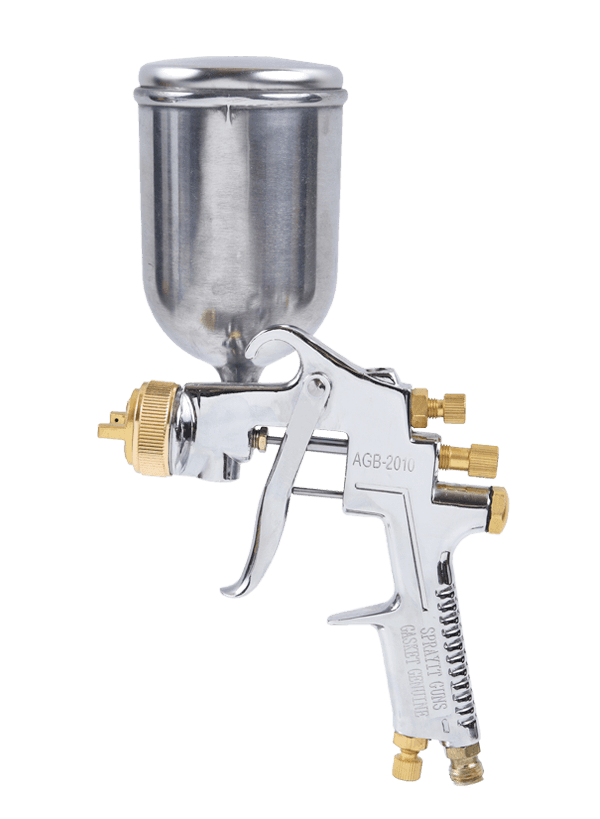

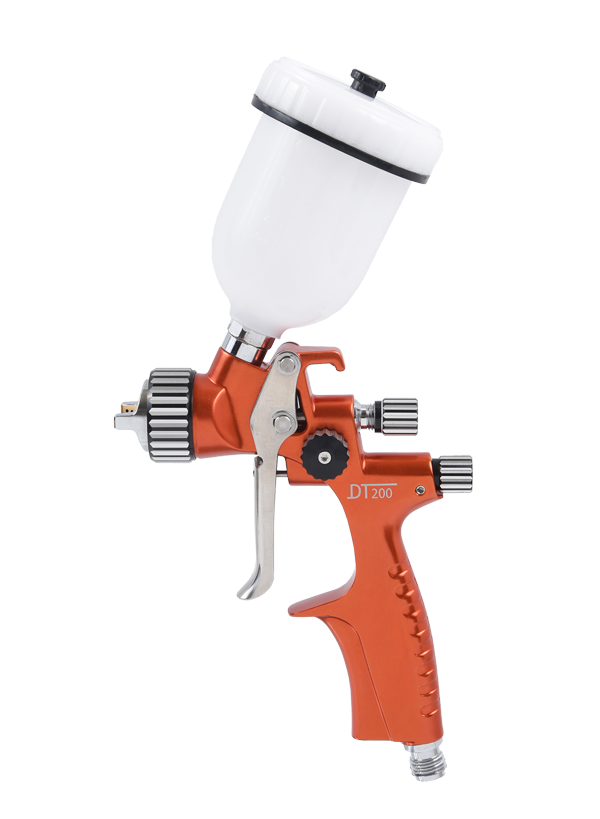

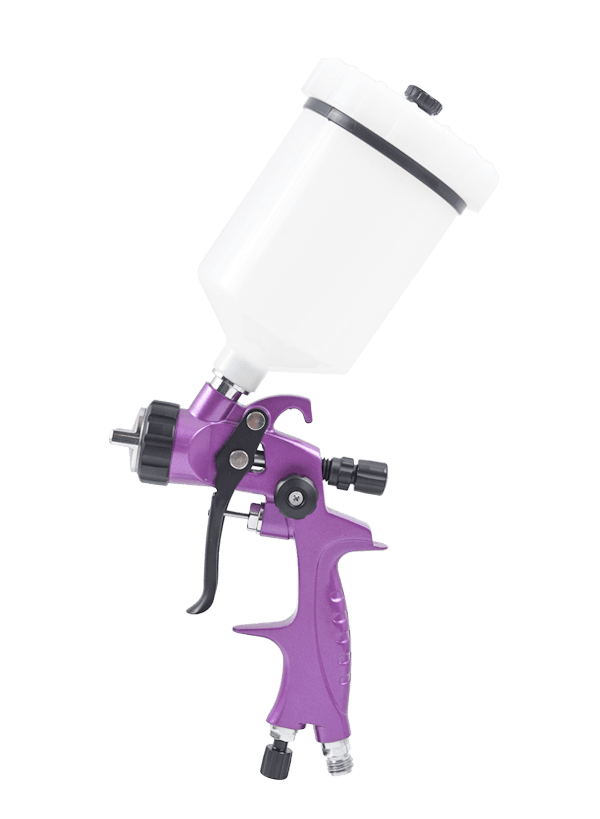

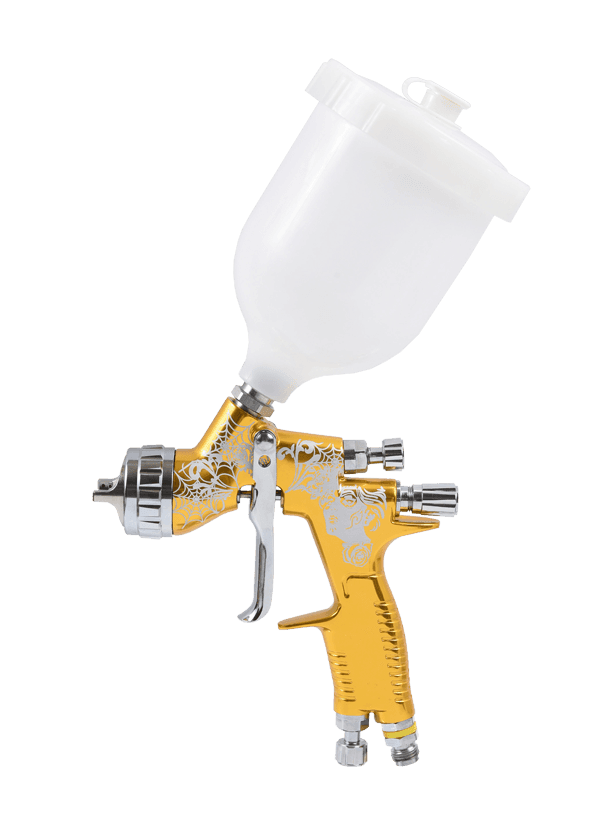

2.Determine Application Method: Contact adhesive can be applied using different methods, including spray guns, rollers, brushes, or handheld applicators. Evaluate which method would be most suitable for your application based on factors like the surface area, accessibility, desired adhesive thickness, and efficiency.

3.Consider Adhesive Viscosity: Different contact adhesives have varying viscosities (thickness). Some applicators are designed to handle thicker adhesives, while others work better with more fluid or low-viscosity adhesives. Ensure compatibility between the adhesive viscosity and the applicator's capabilities.

4.Assess Coverage and Speed Requirements: Evaluate the desired coverage area and application speed. Some applicators, such as spray guns, provide fast and even coverage over large surfaces, making them suitable for larger projects. Rollers and brushes are better suited for smaller areas or detailed work.

5.Evaluate Compatibility: Verify that the contact adhesive applicator is compatible with the specific adhesive you intend to use. Certain applicators may have limitations regarding the type of adhesive they can handle due to chemical compatibility, viscosity, or drying time requirements. Refer to the

Contact Adhesive Spray Gun Factory recommendations or consult with adhesive and applicator suppliers to ensure compatibility.

7.Consider Surface Preparation: Assess the surface preparation requirements for your application. Certain applicators may be more suitable for applying adhesive to smooth surfaces, while others may handle textured or irregular surfaces more effectively. Ensure the chosen applicator can accommodate the surface conditions of your project.

8.Evaluate Equipment Availability and Cost: Consider the availability and cost of the applicator equipment. Evaluate whether you already have access to specific applicators or if you need to purchase or rent them. Take into account the budget constraints of your project and balance cost-effectiveness with the required performance.

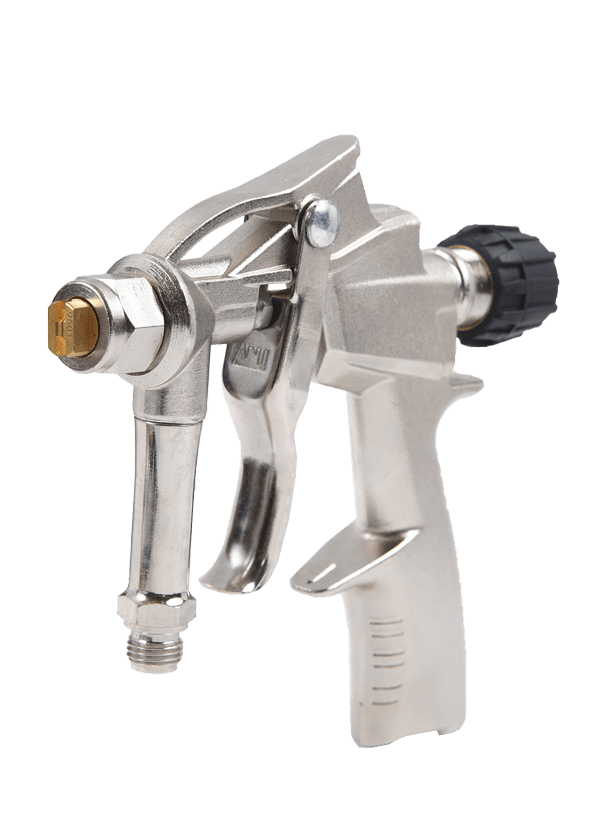

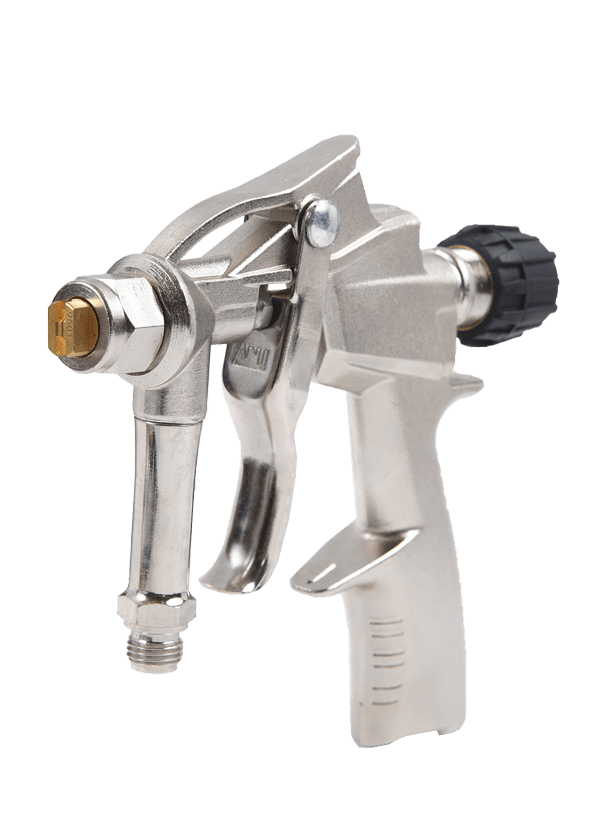

Nozzle model:4001, 6501, 8002, 9501, round

Feeding method;pressure type

Feeding connector:1/4-18NPSM

Maximum working pressure:80bar

Body color:silver (customizable)

Length of spray gun extension tube:240mm, 450mm, 600mm, 800mm