In fact, the selection of the pneumatic spray gun is mainly determined by the use of the tools on the production line. According to the effect of the layer, the amount of air output, the amount of paint, the spraying area, and the additional environmental effects brought by the spray gun during use. It should be noted that the primer mainly plays the role of filling in the coating and increasing the thickness of the coating, so the particle size of the primer is larger, the viscosity is larger, and the specific gravity is larger. The spray gun should have a large diameter nozzle, and the paint storage tank below should be larger. For spraying the topcoat, it has high requirements on the degree of atomization, and a spray gun with a small diameter and good atomization is often used. Combine these reference factors to select the caliber of the spray gun, whether the spray gun is to choose the upper pot or the lower pot, whether it has a pressure feeding type, and so on. In the use of pneumatic spray guns, the main thing is to choose the appropriate caliber, which is the premise of tool purchase in the process of use. If you are not sure, you can consult Ningbo Datian Tools Co., Ltd. to choose the most suitable type of spray gun for you.

When purchasing a spray gun, first debug the tool to see if it is what you need. Then connect the air source, adjust the material pressure and atomizing air pressure to adjust, (different effects have different adjustment methods, but the adjustable range is small, mainly to choose the correct diameter), if you do not understand, you can consult We, Ningbo Datian Tools Co., Ltd., can go to work after adjusting the applicable effects.

In addition, the maintenance work after using the spray gun is also very critical. After use, the thinner of the sprayed paint must be used for spray cleaning until the paint channel of the spray gun is cleaned. Otherwise, the paint in the gun will dry and block, which will affect the normal use of the gun. Specific cleaning method: turn off the compressed air, remove the paint storage tank, pour the paint in the gun back into the paint storage tank, pour the paint in the tank into the container; pour about 1/4 volume of solvent into the paint storage tank to carry out Rinse, install the paint storage tank, connect the compressed air, rock and spray several times; disassemble the nozzle, clean it with solvent and install it; wipe off the paint on the gun body.

The last reminder is to use a soft brush when brushing the spray gun. It is forbidden to use a metal brush, and it is not allowed to use hard objects to poke and scrape, so as to prevent the nozzle from being worn and changing the shape of the jet; secondly, avoid directly soaking the spray gun in the solvent. To prevent the residual paint from adhering to the machine parts and dissolving the lubricating oil on the gun, it can be wiped with a soft cloth dipped in solvent; the knurled parts on the gun are adjusted by hand, avoid using pliers tools; regularly check the needle valve and gun Drop lubricating oil at the pin shaft of the machine; regularly use light grease or Vaseline to lubricate the needle valve and needle valve spring, and do not use oil containing silicon. Only proper operation and maintenance can guarantee the normal use and life of the spray gun.

pneumatic spray gun manufacturers

pneumatic spray gun manufacturers

PRODUCTS SERIES

-

Water-based paint spray gun -HVLP-H-827

-

Water-based paint spray gun -HVLP-1500C

-

Water-based paint spray gun -HVLP-2020

-

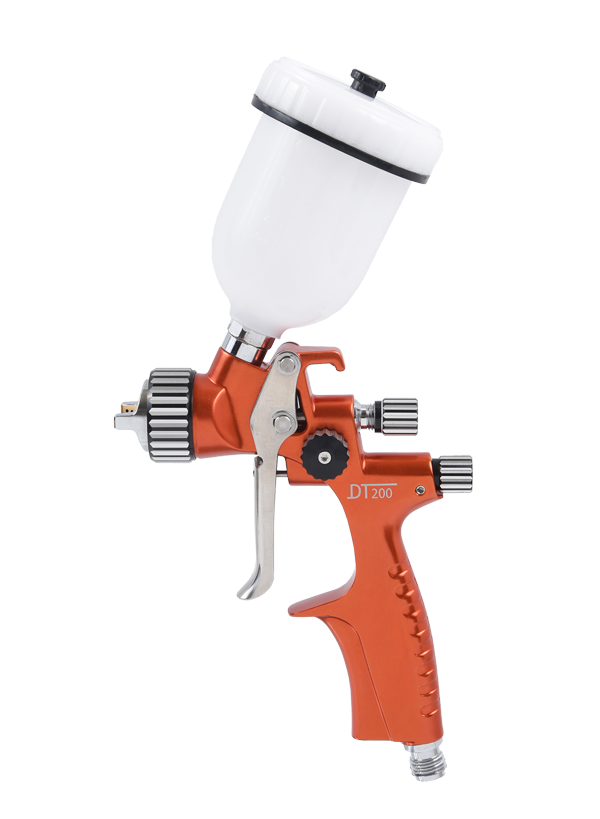

Water-based paint spray gun -HVLP-DT200

-

Water-based paint spray gun -HVLP-E-520

-

Water-based paint spray gun -HVLP-H-827 set-blue

-

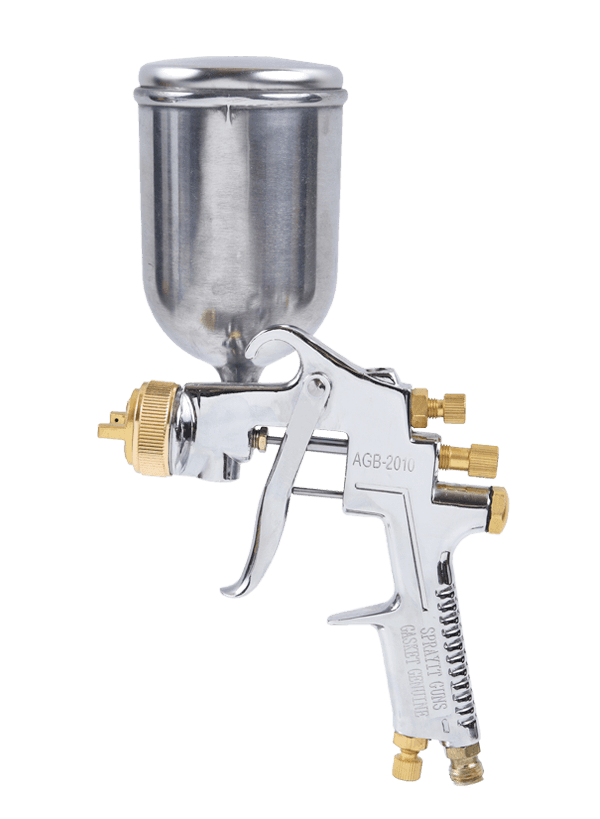

Water-based paint spray gun -HVLP-H-827-Suit-silver

-

Water-based paint spray gun -HVLP-W-10

-

Water-based paint spray gun -HVLP-W-20

-

Water-based paint spray gun -HVLP-W-40

English

English Español

Español