Proper cleaning and maintenance of a spray gun are essential for several reasons:

1.Performance and Efficiency: A clean and well-maintained spray gun ensures optimal performance and efficiency. Over time, paint, coatings, or other materials can build up inside the gun, affecting the spray pattern, flow rate, and overall performance. Pneumatic Spray Gun Factory tell you Regular cleaning prevents clogs, blockages, and uneven spray patterns, resulting in consistent and high-quality finishes.

2.Avoiding Contamination: Contamination can occur when foreign particles or dried paint flakes mix with fresh paint or coatings. This can lead to defects such as surface imperfections, color variations, or even adhesion problems. Proper cleaning helps eliminate any residue or contaminants, ensuring a clean application and preventing potential issues that may arise from contamination.

3.Extending Equipment Lifespan: A well-maintained spray gun lasts longer. Cleaning helps prevent corrosion, which can occur due to prolonged exposure to paint, solvents, or moisture. Regular maintenance, including lubrication of moving parts, ensures smooth operation and reduces wear and tear, extending the lifespan of the spray gun.

4.Cost Savings: Cleaning and maintaining a spray gun properly can result in cost savings. By preventing clogs, blockages, and malfunctions, you can avoid the need for costly repairs or replacements. Additionally, a properly functioning spray gun leads to efficient material usage, reducing waste and saving money on paint or coatings.

5.Safety: Properly cleaning a spray gun promotes safety for both the user and the workplace. Paints, coatings, and solvents used in spray applications can be hazardous if mishandled or improperly stored. Thorough cleaning reduces the risk of chemical reactions or accidents caused by the buildup of flammable or volatile materials. Additionally, a clean spray gun ensures consistent operation, reducing the potential for unexpected issues during use.

The cleaning and maintaining a spray gun properly is vital for achieving consistent, high-quality finishes, preventing contamination, extending the lifespan of the equipment, saving costs, and ensuring a safe working environment. By incorporating regular cleaning and maintenance into your spray gun care routine, you can optimize performance, efficiency, and the longevity of your equipment.

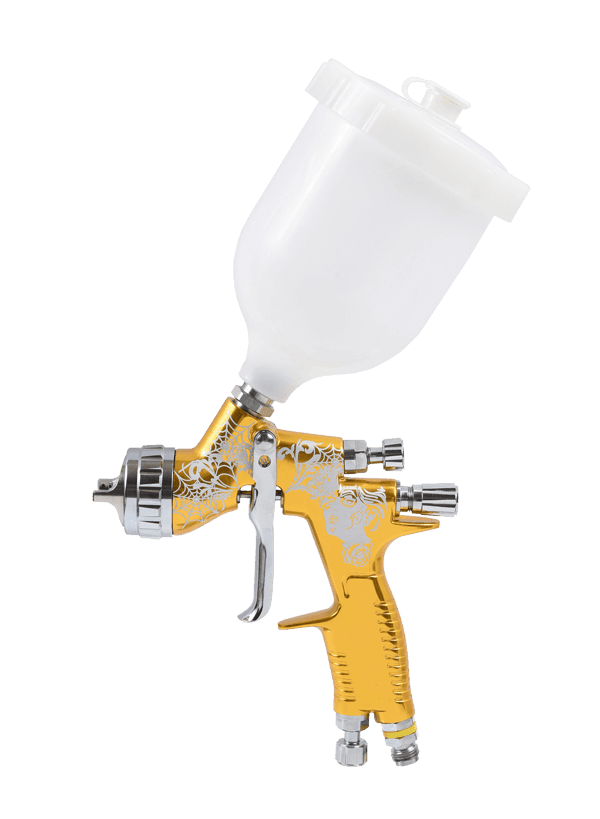

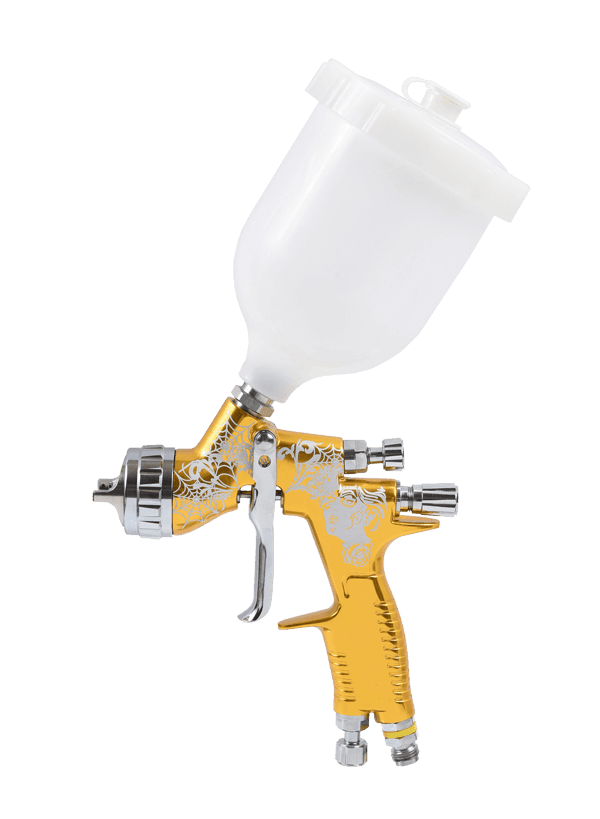

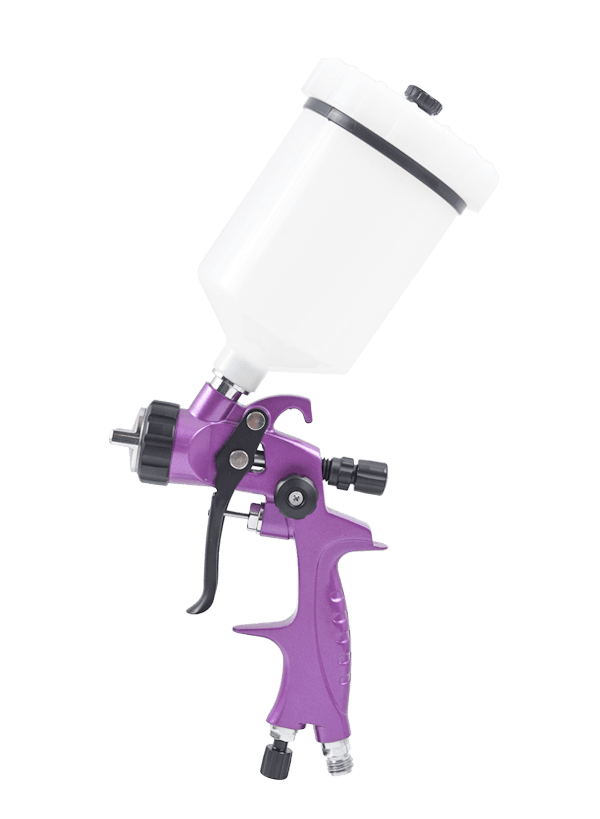

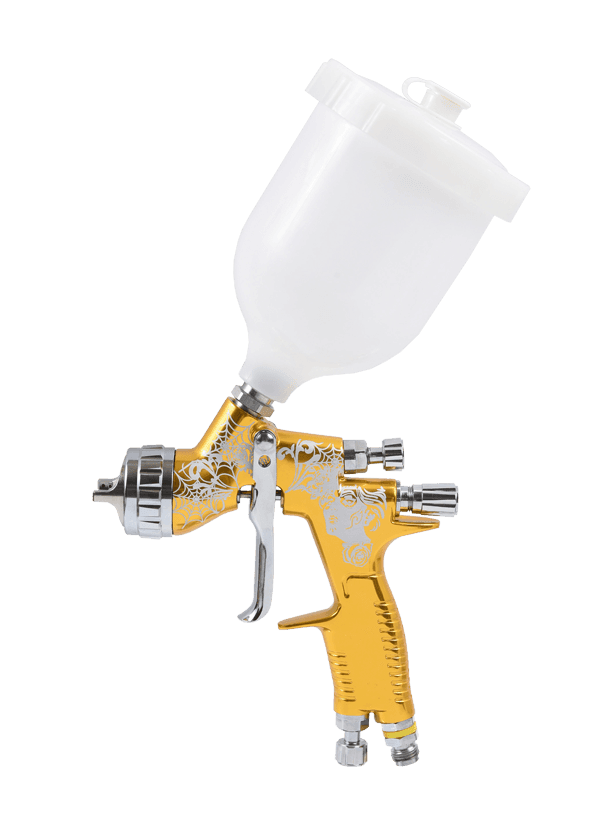

Caliber:1.3mm

Feeding method:gravity type

Cup capacity:600ml

Air inlet connector:1/4"-19" BSP gas pipe connector (Japanese, European, American, and British quick connectors can be equipped)

Working pressure:2~3bar

Gun body color:gold, black

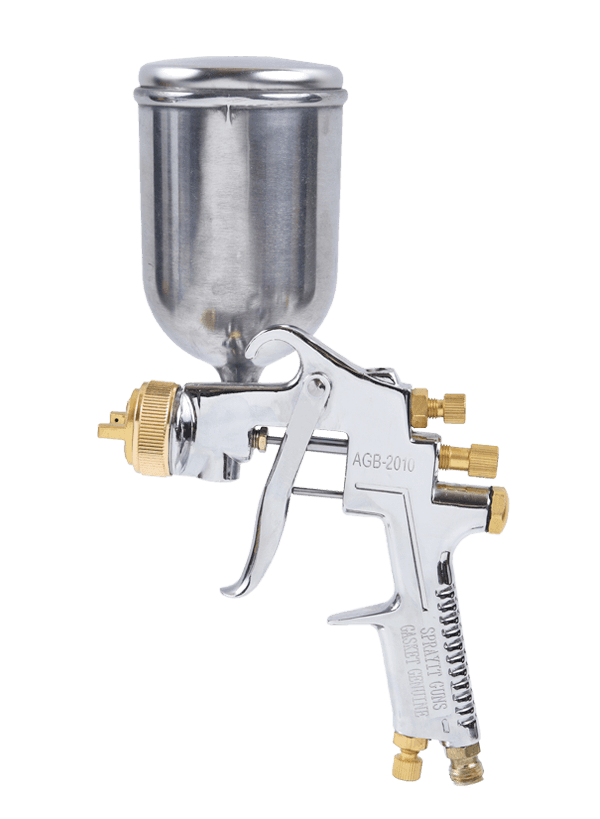

PRODUCTS SERIES

-

Water-based paint spray gun -HVLP-H-827

-

Water-based paint spray gun -HVLP-1500C

-

Water-based paint spray gun -HVLP-2020

-

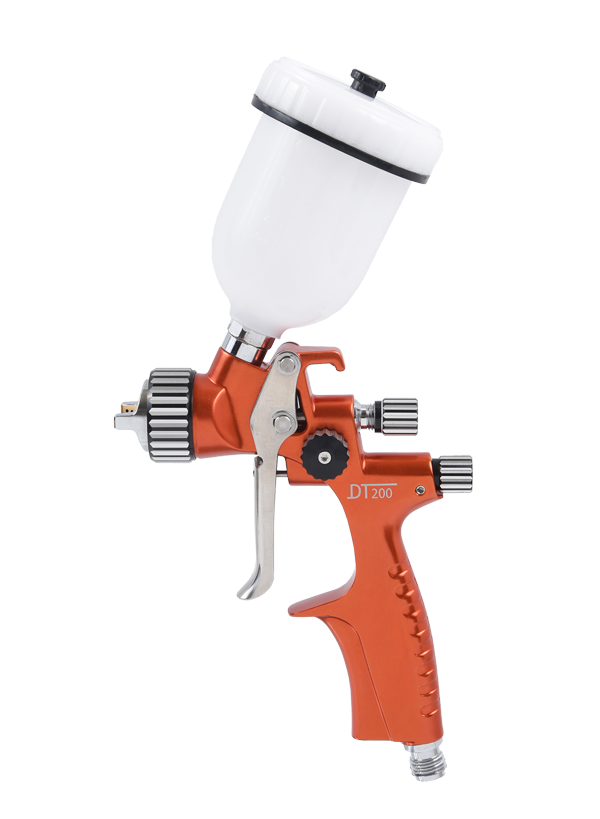

Water-based paint spray gun -HVLP-DT200

-

Water-based paint spray gun -HVLP-E-520

-

Water-based paint spray gun -HVLP-H-827 set-blue

-

Water-based paint spray gun -HVLP-H-827-Suit-silver

-

Water-based paint spray gun -HVLP-W-10

-

Water-based paint spray gun -HVLP-W-20

-

Water-based paint spray gun -HVLP-W-40

English

English Español

Español