Choosing the right cleaning solvent and lubricant for a spray gun is crucial to ensure effective cleaning and proper maintenance. Here are some factors to consider when selecting these products:

1.

Cleaning gun Manufacturers Recommendations: Check the spray gun's manufacturer guidelines or instruction manual. They often provide specific recommendations for cleaning solvents and lubricants that are compatible with their equipment. Following the manufacturer's recommendations ensures optimal performance and prevents potential damage to the spray gun.

2.Compatibility: Ensure that the cleaning solvent and lubricant are compatible with the materials used in your spray gun. Different spray gun components may be made of various materials such as stainless steel, aluminum, plastic, or rubber. Check the product labels or consult the manufacturer to ensure the solvent and lubricant are safe to use with your specific spray gun materials.

3.Cleaning Solvent: Select a cleaning solvent that effectively removes paint, coatings, and residue from the spray gun. Solvents specifically formulated for spray gun cleaning, such as paint thinners or dedicated cleaning solutions, are commonly used. Consider the type of paint or coating you typically work with, as some solvents may be more suitable for certain types of materials or finishes.

4.Lubricant: Choose a lubricant designed for spray guns or similar precision equipment. Look for lubricants that provide corrosion protection, reduce friction, and ensure smooth operation of moving parts. Avoid using heavy oils or greases that may attract dirt or interfere with the spray pattern. Silicone-based lubricants are often recommended for their compatibility with various materials and resistance to drying out.

5.Environmental Considerations: Be mindful of any environmental regulations or restrictions regarding the use and disposal of cleaning solvents. Some solvents may contain volatile organic compounds (VOCs) or other chemicals that require proper handling, storage, and disposal methods. Consider using eco-friendly or low-VOC alternatives if available and appropriate for your application.

It is advisable to consult with the

spray gun manufacturer, experienced professionals, or

Multi-function spray gun Manufacturers to get specific recommendations based on your equipment and application requirements. Following proper cleaning and maintenance practices, using the right solvents and lubricants, will help keep your spray gun in optimal condition, ensuring consistent performance and longevity.

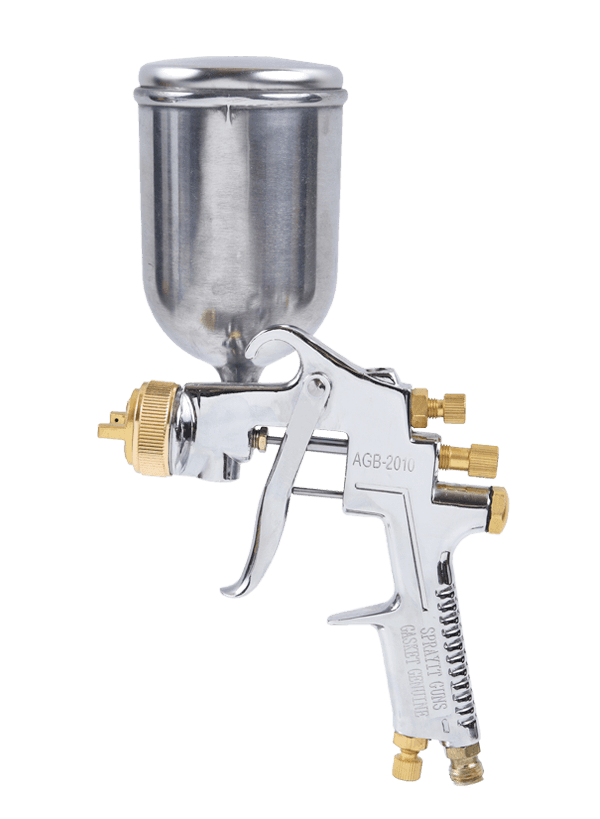

Feeding method:pressure type

Cup capacity:750ml

Air inlet connector:1/4"-19" BSP gas pipe connector (Japanese, European, American, and British quick connectors can be equipped)

Working pressure:6bar

Body color:silver