Hole brushes and patches play important roles in firearm cleaning, specifically in Cleaning Spray Gun. Here's an overview of their roles and China Air Spray Gun Factory tell you how they contribute to effective cleaning:

Hole Brushes:

Hole brushes, also known as bore brushes or barrel brushes, are designed to fit snugly into the barrel of a firearm. They typically consist of a handle with bristles made of materials like nylon, phosphor bronze, or stainless steel. The bristles are attached to the end of the handle in a spiral or loop pattern.

The primary role of a hole brush is to physically remove fouling and debris from the barrel of a firearm. As the brush is inserted into the barrel and twisted or pushed back and forth, the bristles scrape and loosen any accumulated residue such as copper, lead, carbon, or powder fouling. This mechanical action helps break up and dislodge stubborn deposits, ensuring a cleaner barrel.

It's important to choose the correct size and material of the hole brush that corresponds to the caliber and type of firearm being cleaned. Using a brush that matches the barrel's diameter ensures an optimal fit, preventing any damage to the barrel's rifling.

Patches:

Patches are small pieces of cloth or absorbent material, usually made of cotton or flannel, that are used in conjunction with a cleaning rod. They come in various sizes, typically slightly larger than the caliber of the firearm being cleaned.

Patches serve multiple purposes in firearm cleaning:

1.Applying Solvent: Patches are often soaked in a cleaning solvent and then threaded onto the cleaning rod. The solvent-soaked patch is pushed through the barrel, allowing the solvent to penetrate and break down fouling and residue.

2.Removing Fouling: After the solvent has had time to work, clean, dry patches are used to remove the loosened fouling and solvent from the barrel. The patches act as absorbent wipers, effectively picking up the dissolved fouling and debris.

3.Polishing and Drying: Clean, dry patches can be used for a final pass to remove any remaining traces of fouling, ensuring a clean and dry barrel. They also help to polish the barrel and provide a protective layer against corrosion.

4.Patches are typically attached to a jag or loop at the end of the cleaning rod, allowing them to be easily threaded through the barrel and pulled back and forth.

Both hole brushes and patches are essential tools in the cleaning process, with the brush providing mechanical action to remove fouling and the patches assisting in applying solvents, removing residue, and drying the barrel. Using them in combination helps achieve a thorough and effective cleaning of the firearm's barrel, contributing to better accuracy, reliability, and overall firearm performance.

We are famous custom Water-based paint spray gun -HVLP-H-827 set-blue suppliers. We have been focusing on high-quality, professional design and manufacturing concepts. Eliminate changes in product materials and processes to reduce production costs and sales prices. Just to make high-quality products. Our product advantage comes from

1. The factory is fully equipped, the industrial chain is complete, the assembly line has a systematic process, and the 100% finished product testing procedure ensures reliable product quality.

2. Focusing on the development and manufacture of OEM/ODM Water-based paint spray gun -HVLP-H-827 set-blue company for more than 20 years, it has been widely praised in the international market and meets customer requirements.

3. The use of industrial-grade materials, corrosion resistance, to ensure that the service life of the product is more than three times that of ordinary spray guns.

4. Perfect spraying effect, suitable for various spraying occasions.

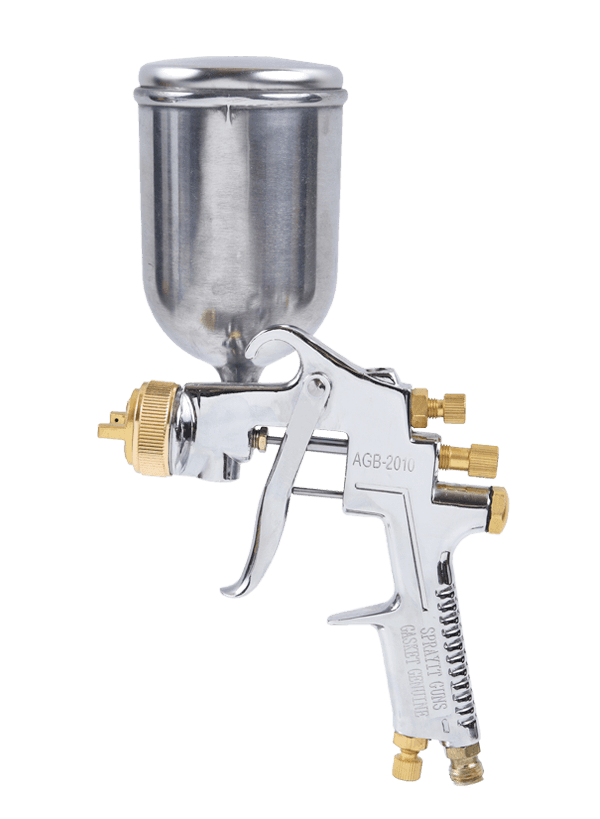

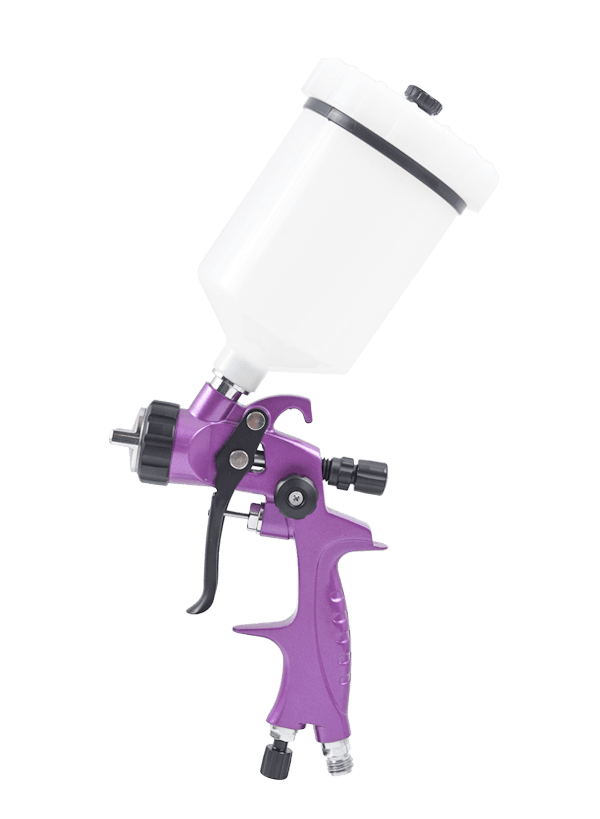

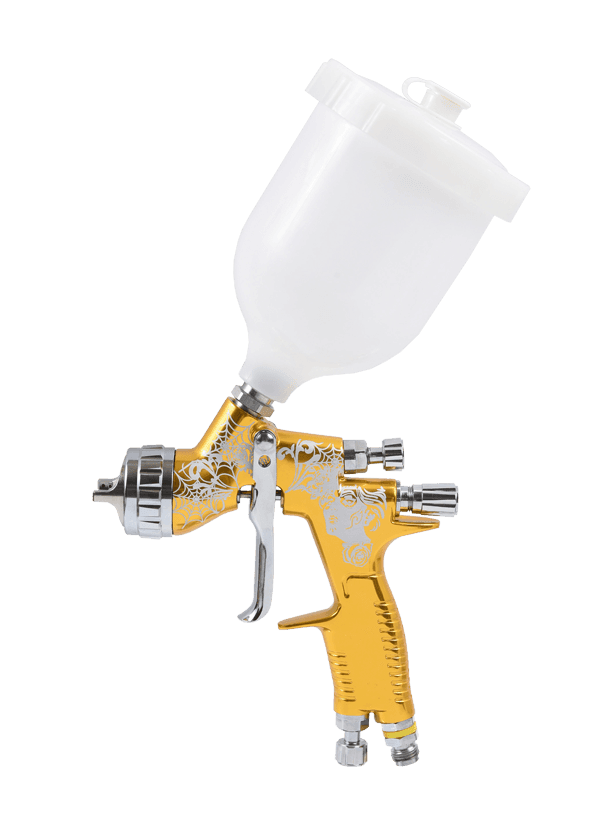

PRODUCTS SERIES

-

Water-based paint spray gun -HVLP-H-827

-

Water-based paint spray gun -HVLP-1500C

-

Water-based paint spray gun -HVLP-2020

-

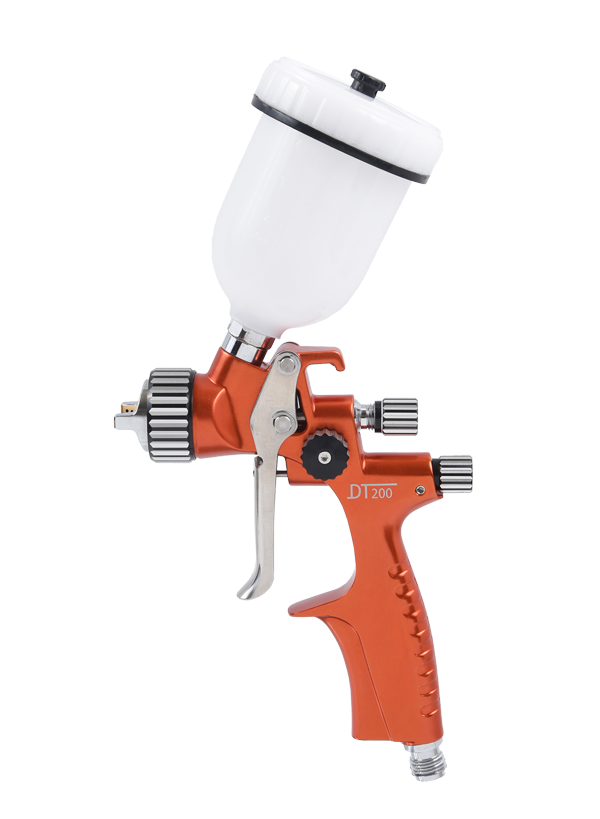

Water-based paint spray gun -HVLP-DT200

-

Water-based paint spray gun -HVLP-E-520

-

Water-based paint spray gun -HVLP-H-827 set-blue

-

Water-based paint spray gun -HVLP-H-827-Suit-silver

-

Water-based paint spray gun -HVLP-W-10

-

Water-based paint spray gun -HVLP-W-20

-

Water-based paint spray gun -HVLP-W-40

English

English Español

Español