Air spray guns operate on the principle of atomization, where compressed air is used to break down liquid coatings into fine particles for even distribution. They typically consist of a nozzle, fluid tip, air cap, and trigger mechanism. Familiarizing yourself with the components and their functions lays the foundation for mastering air spray gun techniques.

Selecting the appropriate air spray gun involves considering factors such as the type of coating, viscosity, desired finish, and target surface. Factors like gun size, nozzle type, and air pressure requirements must align with the coating material's characteristics and the desired outcome.Mastering air spray gun techniques requires practice and attention to detail. Factors like gun-to-surface distance, gun movement speed, and spray pattern adjustment significantly influence the coating's appearance and quality. Understanding the proper spraying techniques, such as overlapping strokes, maintaining consistent gun movement, and controlling trigger action, is essential for achieving a smooth, even coat.

Regular maintenance and proper care are essential for the longevity and performance of air spray guns. China Pneumatic Air Spray Gun Manufacturers thorough cleaning after each use, proper storage, and routine inspection of components ensure consistent functionality and prevent clogs or blockages. Lubrication of moving parts and replacement of worn-out seals or nozzles are also crucial maintenance practices.Safety should be a top priority when working with air spray guns. Proper ventilation, wearing appropriate personal protective equipment (PPE), and understanding the hazards associated with the coating material and solvents are vital. Additionally, following proper grounding procedures to prevent static discharge and understanding the risks of compressed air are key safety measures.

Efficiency is a critical aspect of air spray gun applications. Adjusting air pressure, fluid flow, and pattern control to minimize overspray and optimize transfer efficiency saves on material costs and reduces environmental impact. Understanding the concept of transfer efficiency and implementing techniques to maximize it can significantly improve overall productivity.Identifying and troubleshooting common issues encountered during air spray gun applications can save time and frustration. Problems like uneven spray patterns, orange peel texture, or clogs may stem from issues such as improper air pressure, incorrect fluid viscosity, or damaged equipment. Knowledge of these issues and their remedies ensures smooth and uninterrupted spraying operations.

Mastering the art of air spray guns requires a combination of technical knowledge, practice, and attention to detail. Understanding the fundamentals, choosing the right equipment, and implementing proper spraying techniques are key elements to achieve desired results. Additionally, regular maintenance, adherence to safety protocols, and optimization of efficiency contribute to a successful air spray gun application.

Caliber:0.5mm 0.8mm 1.0mm

Feeding method:gravity type

Cup capacity:100ml

Air inlet connector:1/4"-19" BSP gas pipe connector (Japanese, European, American, and British quick connectors can be equipped)

Working pressure:2bar

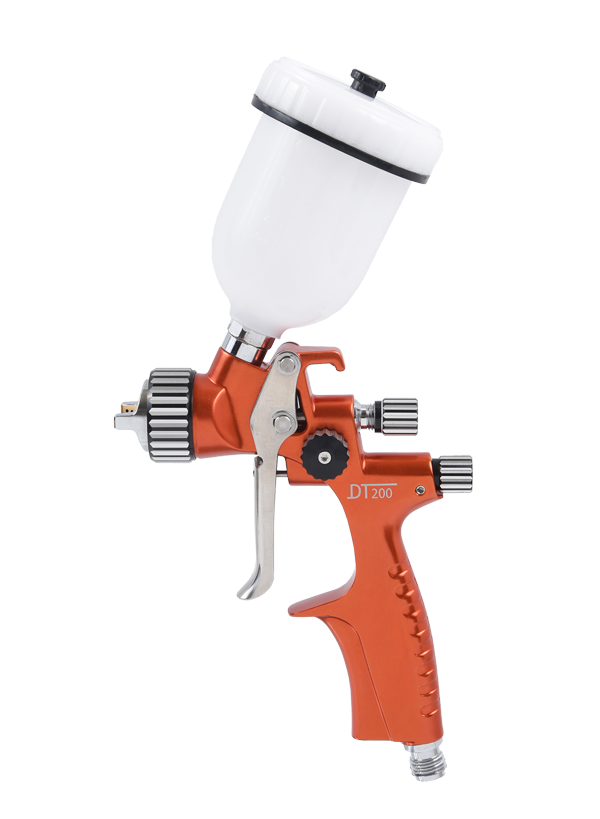

Gun body color:orange, blue

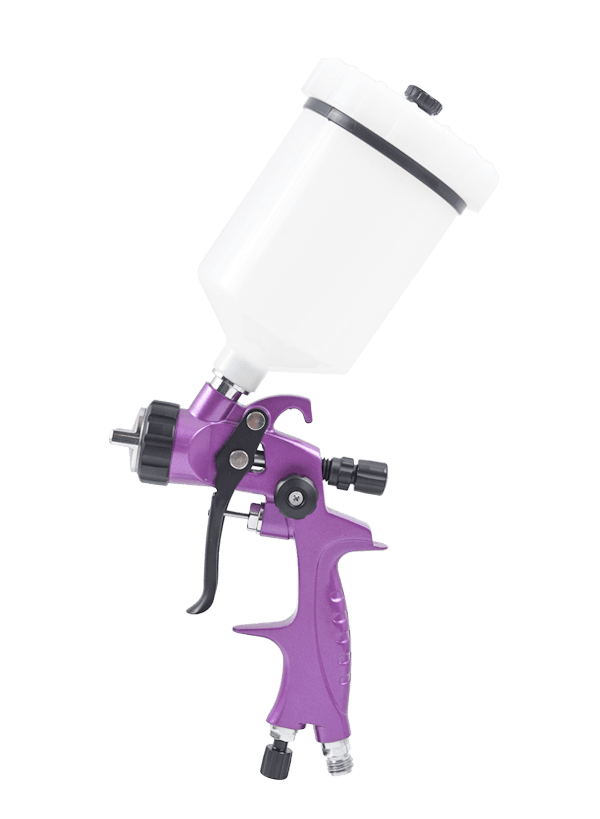

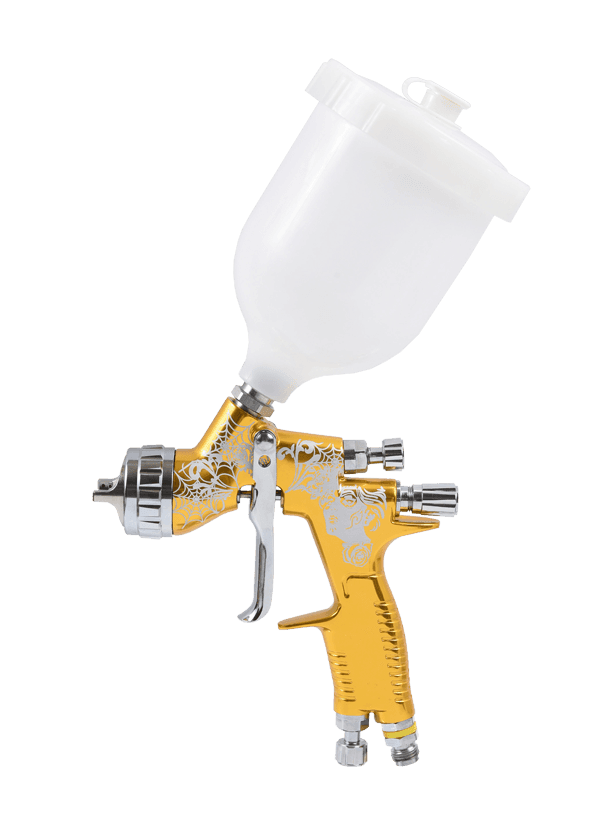

PRODUCTS SERIES

-

Water-based paint spray gun -HVLP-H-827

-

Water-based paint spray gun -HVLP-1500C

-

Water-based paint spray gun -HVLP-2020

-

Water-based paint spray gun -HVLP-DT200

-

Water-based paint spray gun -HVLP-E-520

-

Water-based paint spray gun -HVLP-H-827 set-blue

-

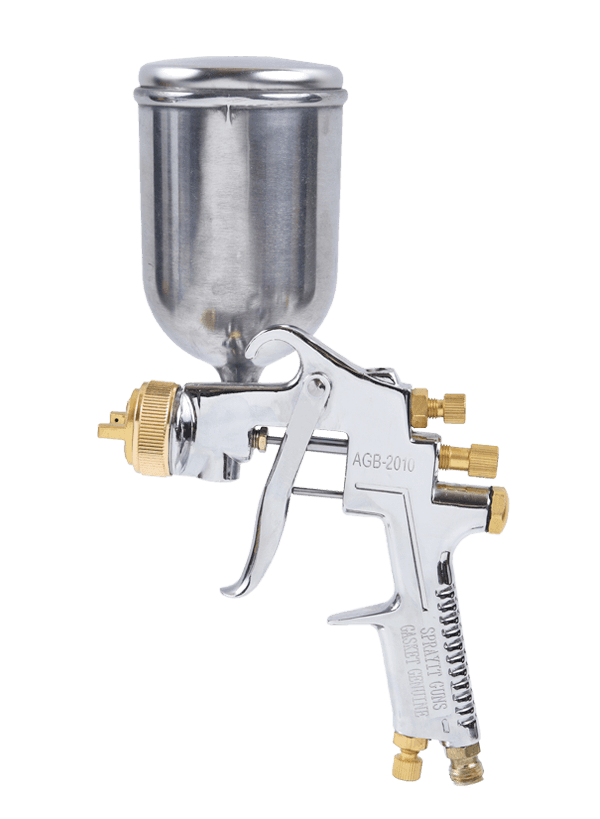

Water-based paint spray gun -HVLP-H-827-Suit-silver

-

Water-based paint spray gun -HVLP-W-10

-

Water-based paint spray gun -HVLP-W-20

-

Water-based paint spray gun -HVLP-W-40

English

English Español

Español