In the actual application process of the spraying system, many people do not pay much attention to the

speed of the spray gun pipeline. They want to take the equipment back. It seems that it is simple to

connect the air pipe to the pipeline and it can be used.

In fact, this is not the case. If you did not notice this in the process of developing the spray system, it

would easily cause a series of problems. For example, the spray gun does not produce paint, the spray

gun does not produce air, etc., which directly reflect the problems on the spray gun. Some are

completely unresponsive.

So these are basically the results of not paying attention to the pipelines of our spraying system. How

should the automatic spraying system layout the pipelines so as not to cause problems?

In the automatic spraying system, the reciprocating machine is equipped with 4 spray guns, and the basic

configuration is a set of 4 separation membrane pumps for oil supply and a set of 5 gallon agitators.

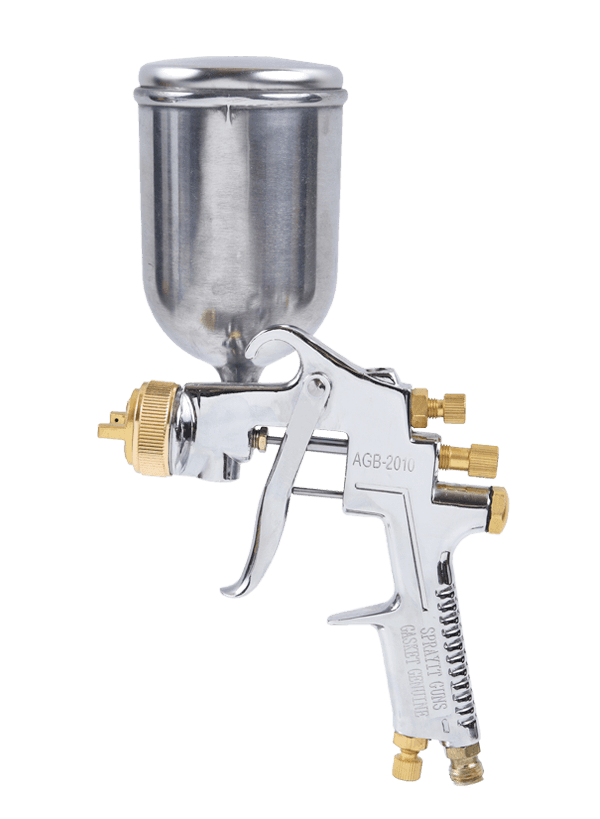

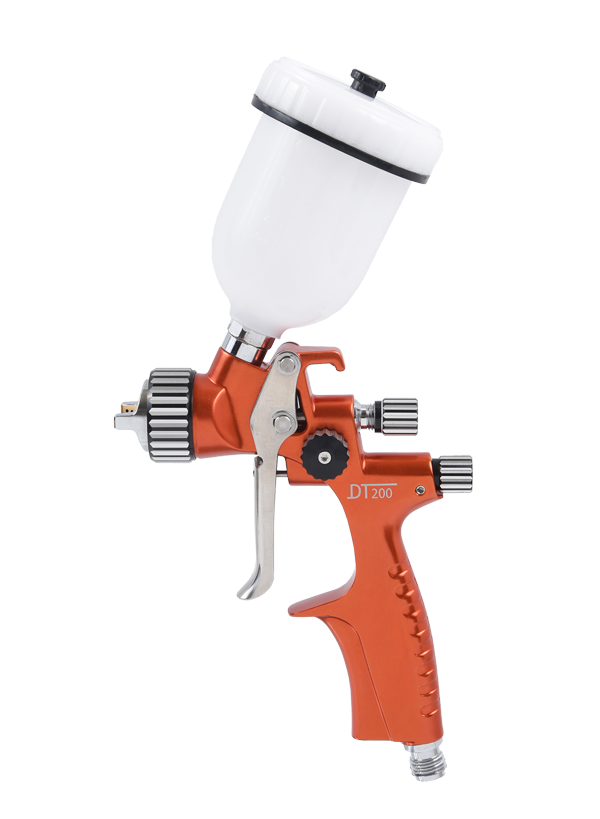

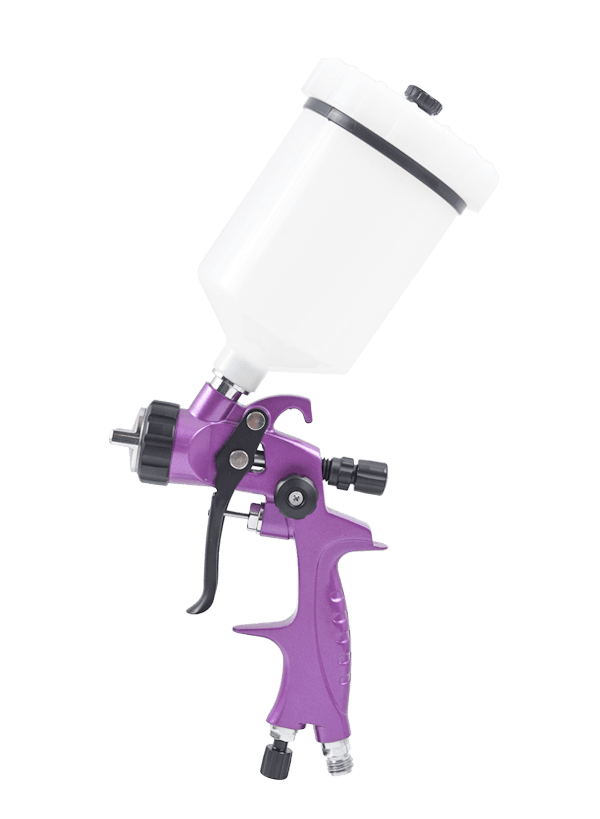

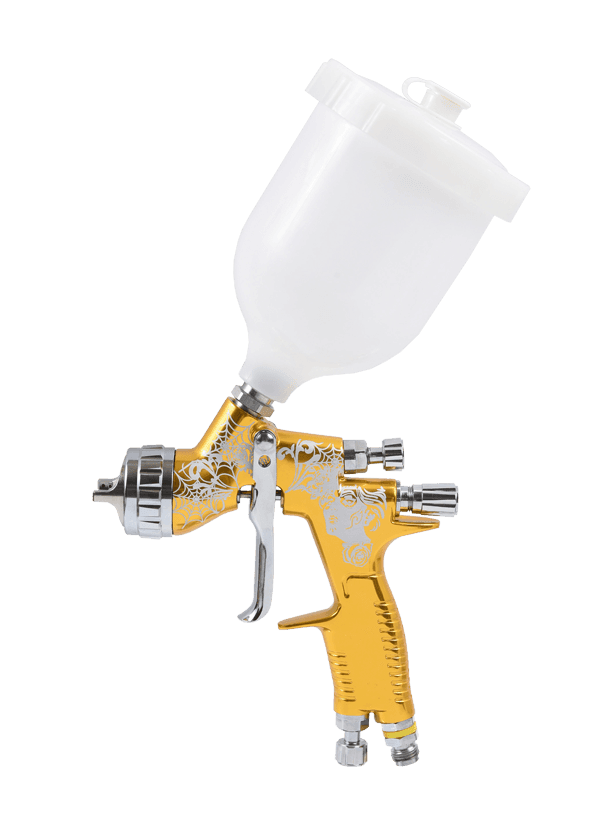

First of all, let's look at the oil circuit, choose 8MM in charge and 6MM in charge. For the spray gun here,

we take the WA-101 caliber 1.0MM (the spray guns of different models and calibers are slightly different).

It should be noted here that whether it is the gas circuit or the oil circuit, it is better to have a larger main

pipe, so as to ensure that the amount of oil or gas is sufficient. The oil circuit is relatively simple. The

supervisor passes the first spray gun, then returns the oil to the second spray gun, and so on until the last

returns the oil into the paint bucket.

The trachea is a little more complicated, but remember that you can’t go wrong. The needle must not be

strung with the atomizer, that is, the CYL hole on the spray gun should not be strung with the atomizer

CAP and FAN, otherwise the spray gun will fail to fire. The main reason is that the amount of air consumed

by the atomization is too large, which will reduce the air pressure of the firing needle, causing the

phenomenon that the spray gun cannot be opened. Therefore, it is best to divide into two supervisors or

three supervisors (with spray gun imported from FAN). In this way, each gas path can be controlled

independently.

In addition, the last point to be emphasized is that the advanced solenoid valve enters the pressure

regulating valve and finally enters the spray gun. Do not make a mistake in this sequence. There are

mistakes in the actual process, mainly because the solenoid valve also has a certain decompression effect.

The air pressure to the spray gun is not very accurate, so the atomization is very well adjusted.

English

English Español

Español